Supply Chain Disruptions: Adapt to 15% Shipping Cost Hike

Navigating the projected 15% increase in shipping costs due to persistent supply chain disruptions requires businesses to implement robust strategies like diversified sourcing, technology adoption, and collaborative partnerships to maintain competitiveness and resilience.

In an increasingly interconnected yet volatile global economy, businesses worldwide are grappling with persistent and evolving challenges within their supply chains. The specter of a projected 15% increase in shipping costs looms large, threatening profit margins and operational stability. Adapting to this new reality demands foresight, agility, and innovative strategies to not only mitigate risks but also transform disruptions into opportunities for enhanced resilience and efficiency.

understanding the currents of disruption

The global supply chain landscape has undergone unprecedented transformations in recent years. What were once considered relatively stable and predictable systems have been repeatedly buffeted by a series of unforeseen events, from geopolitical tensions and natural disasters to public health crises and rapid shifts in consumer demand. These shocks have exposed vulnerabilities inherent in lean, just-in-time models, prompting a reevaluation of traditional approaches to logistics and inventory management.

The cumulative effect of these disruptions is now manifesting as tangible financial pressures, most notably the significant uptick in shipping expenses. This isn’t merely a temporary blip but rather a reflection of systemic issues, including port congestion, labor shortages, fluctuating fuel prices, and a strained global shipping capacity. Understanding the multifaceted nature of these currents is the first step toward charting a resilient course for businesses.

the ripple effect of increased costs

A 15% surge in shipping costs is far more than an abstract number; it translates into a cascade of operational and financial consequences across the entire business ecosystem. For manufacturers, it means higher input costs for raw materials and components, potentially eroding profit margins unless these increases can be absorbed or passed on. Retailers face similar predicaments, as the cost of bringing goods from factories to store shelves or customer doorsteps escalates.

- Erosion of Profit Margins: Businesses operating on thin margins will find it increasingly difficult to absorb these cost increases, leading to reduced profitability if not managed proactively.

- Higher Consumer Prices: To offset rising expenses, companies may be forced to pass on costs to consumers, potentially fueling inflation and impacting purchasing power.

- Supply Chain Volatility: Unpredictable shipping costs add another layer of complexity to demand forecasting and inventory planning, making it harder to maintain optimal stock levels.

Beyond the immediate financial implications, increased shipping costs can also influence strategic decisions, such as market entry, product pricing, and even global sourcing strategies. Companies might reconsider long-distance supply routes in favor of more localized or regional alternatives to mitigate transit risks and costs.

leveraging technology for supply chain resilience

In the face of escalating shipping costs and persistent disruptions, technology emerges as an indispensable tool for building more resilient and adaptable supply chains. From advanced analytics and artificial intelligence to blockchain and the Internet of Things (IoT), these innovations offer unparalleled opportunities for enhanced visibility, efficiency, and predictive capabilities. Businesses that proactively embrace digital transformation are better positioned to navigate the complexities of the modern global economy.

The adoption of sophisticated technological solutions allows companies to move beyond reactive problem-solving toward a more proactive, data-driven approach to supply chain management. This involves not only optimizing existing processes but also exploring entirely new ways of operating that can mitigate the impact of external shocks and cost pressures.

advanced analytics and ai for foresight

Predictive analytics and artificial intelligence (AI) are transforming how businesses anticipate and respond to supply chain challenges. By analyzing vast datasets—including historical shipping costs, weather patterns, geopolitical events, and consumer trends—AI algorithms can forecast potential disruptions and cost fluctuations with remarkable accuracy. This foresight enables companies to make more informed decisions regarding inventory levels, transportation modes, and supplier selection.

- Demand Forecasting: AI-powered models can predict shifts in consumer demand, allowing businesses to optimize production and inventory, reducing the need for costly expedited shipping.

- Route Optimization: Algorithms can identify the most cost-effective and efficient shipping routes, taking into account current traffic, weather, and congestion at ports.

- Risk Assessment: AI can analyze global events to predict potential choke points or disruptions, allowing companies to pre-emptively adjust their strategies.

The ability to predict future scenarios empowers businesses to avoid bottlenecks before they occur, allocate resources more effectively, and negotiate better rates by anticipating market shifts. This proactive stance is crucial for mitigating the impact of rising shipping costs.

blockchain for transparency and trust

Blockchain technology, often associated with cryptocurrencies, offers significant potential for enhancing supply chain transparency and trust. By creating an immutable, distributed ledger of all transactions and movements within the supply chain, blockchain provides a single source of truth that can be accessed by all authorized participants. This increased visibility helps in tracing goods, verifying authenticity, and streamlining customs procedures.

For high-value or time-sensitive goods, blockchain can reduce delays caused by paperwork and manual verification, potentially lowering associated costs. Furthermore, it can help identify inefficiencies and fraudulent activities that might contribute to overall supply chain expenditures.

iot for real-time visibility

The Internet of Things (IoT) enables real-time tracking and monitoring of goods in transit. Sensors attached to shipments can provide data on location, temperature, humidity, and even potential tampering. This real-time visibility allows businesses to react immediately to deviations from planned routes or conditions, preventing spoilage, loss, or delays that can add to costs.

By having precise information about the whereabouts and condition of their inventory, companies can better manage their logistics, optimize warehousing, and ensure timely deliveries, all of which contribute to cost savings and improved customer satisfaction.

diversifying sourcing and manufacturing strategies

For many years, the conventional wisdom in supply chain management leaned heavily towards globalization and concentrating production in regions offering the lowest labor and production costs. However, recent disruptions have underscored the inherent risks associated with such highly centralized models. A single point of failure—be it a factory shutdown, a port closure, or geopolitical tariffs—can have enormous reverberations across an entire global operation.

As a direct response to these vulnerabilities and the rising costs tied to extended supply lines, businesses are now strategically re-evaluating their sourcing and manufacturing footprints. This pivot involves a conscious move towards diversification, reducing over-reliance on any single country or supplier and building a more distributed and resilient network. This strategy aims to enhance supply chain stability and offer greater flexibility in responding to market dynamics and cost pressures, including the projected 15% rise in shipping expenses.

nearshoring and reshoring initiatives

Nearshoring, the practice of moving production closer to primary markets (often within the same continent), and reshoring, bringing manufacturing back to the home country, are gaining significant traction. While these approaches may entail slightly higher production costs due to different labor rates or regulatory environments, they offer substantial advantages in terms of reduced shipping times, lower transportation costs, and increased control over the manufacturing process.

- Reduced Lead Times: Shorter distances mean quicker delivery of goods, allowing for greater responsiveness to market changes and potentially reducing inventory holding costs.

- Lower Shipping Costs: Less reliance on intercontinental sea or air freight can directly mitigate the impact of rising shipping expenses.

- Enhanced Control: Proximity to manufacturing facilities allows for better oversight of quality, labor practices, and intellectual property.

Furthermore, nearshoring can simplify logistics, reduce customs complexities, and foster stronger relationships with local suppliers, creating a more cohesive and responsive supply network. This strategic shift is vital in mitigating the impact of long-distance logistical vulnerabilities and the associated cost hikes.

multi-sourcing beyond a single region

Another critical aspect of diversification is multi-sourcing, which involves procuring raw materials and components from multiple suppliers located in different geographic regions. This strategy ensures that if one source is disrupted, alternative suppliers can step in, minimizing supply chain interruptions. It also creates a competitive environment among suppliers, potentially leading to better pricing and more favorable terms.

While managing multiple supplier relationships can add administrative complexity, the benefits of enhanced resilience often outweigh these challenges, especially when considering the significant costs incurred during a complete supply chain breakdown. Multi-sourcing acts as a vital buffer against regional instability or localized operational issues.

optimizing logistics and inventory management

Amidst rising shipping costs, the precision with which businesses manage their internal logistics and inventory becomes paramount. Outdated or inefficient practices in these areas can amplify the impact of external cost pressures, leading to unnecessary expenses and operational bottlenecks. A strategic overhaul of these processes is essential for achieving operational leaness and cost-effectiveness in a challenging economic climate.

The goal is not simply to cut costs but to optimize the flow of goods from source to consumer, ensuring that inventory is available when and where it’s needed, without incurring excessive holding or expedited shipping charges. This requires a delicate balance and a commitment to continuous improvement in logistical operations.

streamlining warehousing and distribution

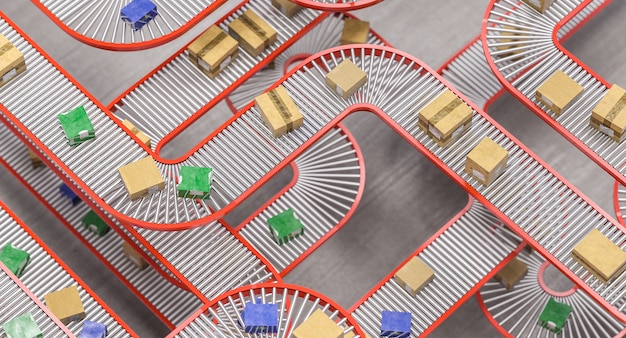

Efficient warehousing and distribution networks are central to mitigating increased shipping expenditures. This includes optimizing warehouse layouts, implementing advanced inventory management systems, and strategically locating distribution centers to minimize last-mile delivery costs. Automation within warehouses, such as robotic picking systems, can also significantly reduce labor costs and improve throughput efficiency.

Furthermore, exploring shared warehousing options or collaborating with third-party logistics (3PL) providers can offer economies of scale, allowing businesses to leverage existing infrastructure and expertise without the substantial capital investment required for building and maintaining their own facilities. Such partnerships can unlock efficiencies that are difficult for individual companies to achieve on their own.

just-in-case inventory strategy

The “just-in-time” (JIT) inventory philosophy, while lauded for its efficiency, proved vulnerable during recent widespread disruptions. As a result, many businesses are adopting a more balanced “just-in-case” (JIC) approach, holding slightly larger buffer stocks of critical components or finished goods. While this may increase inventory holding costs, it provides a crucial safety net against unforeseen supply interruptions and the need for costly emergency shipments.

The key lies in finding the optimal balance—enough buffer to prevent stockouts and production halts, but not so much as to create excessive carrying costs. This requires sophisticated demand forecasting and careful analysis of supply chain lead times and variability. Strategic JIC inventory can be a powerful defense against the cascading effects of shipping cost increases, ensuring continuous operation even when external conditions are challenging.

optimizing freight and carrier management

Effective freight management goes beyond simply choosing the cheapest carrier. It involves a comprehensive strategy that includes consolidating shipments, negotiating favorable contracts with multiple carriers, and utilizing freight optimization software. LTL (less-than-truckload) or FTL (full-truckload) shipping decisions should be based on careful analysis of volume, destination, and urgency.

Working with freight brokers or logistics platforms can also provide access to a wider network of carriers and better rates, especially for businesses with fluctuating shipping volumes. Regular review and negotiation of carrier contracts are vital to ensure businesses are always securing the most competitive rates available, helping to offset the overall increase in shipping expenses.

fostering collaboration and partnerships

In a global economy marked by complex challenges, the era of isolated, competitive supply chains is giving way to a more collaborative paradigm. Businesses are increasingly recognizing that overcoming systemic disruptions and managing escalating costs, such as the projected 15% increase in shipping expenses, requires collective action. Forming strategic partnerships and fostering collaboration across the supply chain can unlock shared efficiencies, enhance visibility, and distribute risk more effectively.

This approach moves beyond traditional buyer-supplier relationships toward more integrated, mutually beneficial alliances. Such partnerships can range from direct collaboration with key suppliers and logistics providers to participation in industry-wide initiatives aimed at improving overall supply chain resilience and practices.

strategic supplier relationships

Building strong, long-term relationships with key suppliers is fundamental. This means moving beyond transactional interactions to foster genuine partnerships characterized by mutual trust, transparency, and shared goals. When suppliers are viewed as extensions of a company’s own operations, there’s a greater willingness to share information, collaborate on forecasting, and work together to resolve issues, including unexpected cost increases.

- Information Sharing: Open communication channels allow for better demand forecasting and production planning, reducing surprises and enabling proactive adjustments.

- Joint Problem-Solving: Collaborative efforts can lead to innovative solutions for sourcing, manufacturing, and logistics challenges, benefiting both parties.

- Contractual Flexibility: Strong relationships can result in more flexible contracts that accommodate market volatility and provide safeguards against sudden cost spikes.

These deeper relationships create a robust network that is better equipped to absorb shocks and manage costs collectively, rather than individually. This cooperative spirit becomes a competitive advantage in a volatile marketplace.

partnering with logistics providers (4pl/5pl)

Engaging with strategic logistics partners, particularly 4PL (Fourth-Party Logistics) or 5PL (Fifth-Party Logistics) providers, can significantly enhance a company’s logistical capabilities. These partners often possess extensive networks, advanced technological infrastructure, and deep expertise in global freight optimization. A 4PL acts as an integrator, managing all aspects of a client’s supply chain, while a 5PL goes a step further, focusing on supply chain consulting and optimization, often leveraging emerging technologies.

By outsourcing complex logistics operations to these specialized providers, businesses can tap into economies of scale, access cutting-edge tools, and leverage expert knowledge that might be prohibitively expensive to develop internally. This strategic partnership model allows companies to focus on their core competencies while benefiting from optimized, cost-effective logistics, which is crucial when facing rising shipping costs.

industry collaboration and data sharing

Beyond individual partnerships, industry-wide collaboration can play a pivotal role in addressing systemic supply chain challenges. This includes participation in industry forums, data-sharing initiatives, and joint ventures aimed at improving infrastructure, standardizing processes, or lobbying for favorable trade policies. Sharing anonymized data on supply chain bottlenecks, shipping costs, and capacity issues can provide valuable insights that benefit all participants.

For example, collaborative efforts to digitize port operations or develop shared tracking systems can reduce congestion and improve efficiency across the board. By working together, competing businesses can collectively raise the bar for supply chain resilience, creating a more robust and predictable environment for all.

strategic financial planning and risk mitigation

The projected 15% increase in shipping costs is not just an operational challenge; it is a significant financial one. Businesses must integrate robust financial planning and sophisticated risk mitigation strategies directly into their supply chain management frameworks. This involves more than just budgeting for higher expenses; it demands a proactive approach to forecasting, hedging, and building financial resilience to absorb or offset these inevitable cost surges.

Effective financial stewardship in this context means understanding the full financial implications of supply chain decisions, from sourcing location to inventory levels, and implementing measures to protect profitability and cash flow. It’s about turning potential liabilities into manageable risks through astute financial foresight.

cost pass-through and pricing strategies

One of the most direct ways to address rising shipping costs is through strategic pricing. However, simply passing on the entire cost increase to the consumer can be detrimental to sales and market share. Businesses must carefully analyze market elasticity, competitive pricing, and consumer tolerance for price adjustments. This might involve a multi-pronged approach:

Sometimes, a direct price increase is unavoidable, but it should be communicated transparently. Alternatively, businesses might explore new pricing models, such as dynamic pricing based on real-time shipping costs, or offer tiered service levels where customers can choose between slower, cheaper shipping and faster, more expensive options. Bundling products or offering loyalty programs can also help absorb minor price adjustments without alienating customers.

hedging and financial instruments

For businesses with significant exposure to fluctuating freight rates or fuel costs, financial hedging instruments can offer a degree of predictability. Futures contracts for fuel, or freight forward agreements, allow companies to lock in prices for future shipments, providing certainty in an otherwise volatile market. While hedging involves its own risks and complexities, it can be a valuable tool for managing large, unpredictable cost variables.

This strategy requires careful analysis of market trends and expert financial advisement, but it can shield a company from sudden, drastic price swings that might otherwise cripple profitability. It turns uncertain future costs into more predictable current expenses.

building financial reserves and insurance

Maintaining adequate financial reserves is a fundamental aspect of resilience. A healthy cash buffer allows businesses to absorb temporary cost spikes or invest in immediate solutions without jeopardizing liquidity. This financial cushion prevents knee-jerk, often expensive, reactions to market changes and provides the flexibility to implement long-term strategic adjustments.

Additionally, comprehensive supply chain insurance policies can provide a safety net against various risks, including cargo damage, loss, or significant delays. While insurance doesn’t prevent disruptions, it can mitigate their financial impact, helping businesses recover lost revenues or cover unexpected expenses associated with a disrupted supply chain. Selecting the right policy requires a deep understanding of potential vulnerabilities and their associated costs.

embrace sustainability and ethical practices

The contemporary business landscape increasingly intertwines economic viability with ethical and sustainable practices. While often viewed through the lens of corporate social responsibility, integrating sustainability into supply chain operations can also be a powerful strategy for mitigating long-term costs, enhancing brand reputation, and future-proofing against evolving regulations. As shipping costs rise, optimizing for environmental impact often aligns with cost reduction efforts.

Sustainable supply chain management can lead to significant operational efficiencies, resource conservation, and reduced waste, all of which contribute to a leaner, more resilient business model. Moreover, consumers and investors are increasingly scrutinizing the environmental and social footprint of companies, making sustainable practices a competitive imperative.

reducing carbon footprint and optimizing routes

Efforts to reduce carbon emissions within the supply chain often lead directly to cost savings in freight. Optimizing transport routes, utilizing more fuel-efficient modes of transportation (e.g., shifting from air to sea or rail where feasible), and consolidating shipments can collectively lower fuel consumption and reduce overall shipping expenses. Investing in electric vehicles for last-mile delivery, for instance, can mitigate exposure to volatile fossil fuel prices in the long run.

- Mode Shift: Prioritizing slower, more carbon-efficient transport modes like sea or rail for non-urgent shipments reduces both emissions and cost per unit.

- Route Optimization Software: Advanced systems help plan the shortest, most fuel-efficient routes, minimizing mileage and associated costs.

- Backhauling: Utilizing empty return trips for new shipments reduces dead mileage and maximizes transport efficiency.

These practices not only contribute to environmental goals but also directly address the challenge of rising operational costs stemming from transportation, offering a dual benefit to companies committed to both fiscal and environmental health.

circular economy principles

Embracing circular economy principles—which emphasize reducing, reusing, and recycling materials—can significantly impact supply chain costs. By designing products for longevity, ease of repair, and recyclability, businesses can reduce their reliance on new raw material extraction and associated procurement and transportation costs. Establishing reverse logistics systems for product returns, repairs, or recycling streams creates new value and reduces waste disposal expenses.

For example, a company that designs durable, modular products and offers repair services reduces the need for customers to purchase entirely new items, leading to fewer shipments of new goods and a smaller environmental footprint. This approach can also foster customer loyalty and differentiate a brand in the marketplace, providing long-term strategic benefits.

ethical sourcing and labor practices

While not directly tied to shipping costs, ethical sourcing and fair labor practices contribute to overall supply chain stability and reputation. Companies with robust ethical frameworks are less likely to face costly reputational damage, boycotts, or supply disruptions due to labor disputes or human rights violations in their supply chain. Investing in responsible sourcing can also lead to more stable supplier relationships and a higher quality, more reliable product flow.

Furthermore, avoiding suppliers with questionable practices can shield a business from potential legal liabilities or regulatory fines. A strong ethical foundation ensures long-term sustainability and reduces unforeseen costs associated with corrective actions or brand remediation, reinforcing resilience across the entire supply chain.

| Key Strategy | Brief Description |

|---|---|

| 📊 Tech Adoption | Leverage AI, IoT, and blockchain for predictive analytics, real-time tracking, and enhanced transparency to optimize operations. |

| 🌍 Diversified Sourcing | Implement nearshoring, reshoring, and multi-sourcing to reduce reliance on single regions and shorten supply lines. |

| 📦 Logistics Optimization | Optimize warehousing, adopt a “just-in-case” inventory approach, and manage freight efficiently to cut costs. |

| 🤝 Collaborative Partnerships | Foster strong relationships with suppliers and 4PL/5PL providers for shared efficiencies and risk mitigation. |

frequently asked questions

▼

Global shipping costs are escalating due to a confluence of factors, including persistent port congestion, labor shortages, high demand for goods, disruptions from geopolitical events, and fluctuating fuel prices. The ripple effects of these challenges create an imbalance between available shipping capacity and demand, driving prices upward across the industry.

▼

Nearshoring involves moving production or operations to a nearby country, often within the same continent, as opposed to distant overseas locations. This strategy directly helps reduce shipping costs by shortening transportation distances, minimizing reliance on intercontinental freight, and often simplifying logistics and customs procedures. It offers a balance between global sourcing benefits and regional proximity.

▼

AI improves supply chain resilience by enabling more accurate demand forecasting, optimizing shipping routes for efficiency, and identifying potential disruptions proactively through predictive analytics. AI algorithms can analyze vast datasets to anticipate cost fluctuations and recommend strategic adjustments, allowing businesses to make informed decisions that mitigate the impact of rising shipping expenses and operational bottlenecks.

▼

While “just-in-time” (JIT) minimizes inventory holding costs, its extreme lean nature has proven vulnerable to large-scale, unpredictable disruptions. Many businesses are now adopting a hybrid “just-in-case” (JIC) approach, maintaining strategic buffer stocks for critical components. The viability of JIT depends on specific industry and product characteristics, balancing efficiency gains against the risk of costly stockouts and emergency shipments.

▼

Integrating sustainable practices offers multiple benefits beyond direct cost savings. It enhances brand reputation, improves customer loyalty, and attracts environmentally conscious investors. Furthermore, it helps companies comply with evolving regulations, reduces waste, conserves resources, and fosters a more resilient and ethically responsible supply chain against future environmental and social challenges, contributing to long-term business viability.

conclusion

The projected 15% increase in shipping costs is a formidable challenge for businesses, but it is not an insurmountable one. By embracing a multi-faceted approach that integrates technological innovation, diversified sourcing strategies, optimized logistics, and strong collaborative partnerships, companies can not only mitigate the immediate financial impact but also build profoundly more resilient and adaptable supply chains for the future. The era of predictable global logistics has evolved; success now hinges on agility, foresight, and a willingness to rethink conventional approaches to navigate the dynamic currents of supply chain disruptions.