The Impact of 3D Printing on US Aerospace: Cost Reduction & Efficiency

The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency is transforming manufacturing by enabling faster prototyping, lighter components, and customized solutions, thereby significantly reducing production costs and boosting efficiency.

The US aerospace industry is undergoing a significant transformation, and at the heart of this change lies the innovative technology of 3D printing. Also known as additive manufacturing, 3D printing is revolutionizing how aircraft components are designed, produced, and integrated.

The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency is far-reaching, from accelerating prototyping to enabling the creation of complex geometries previously impossible to manufacture. What are the key ways 3D printing is impacting the aerospace sector, and how can companies leverage this technology to gain a competitive edge? This article explores these questions in detail.

Understanding the Basics of 3D Printing in Aerospace

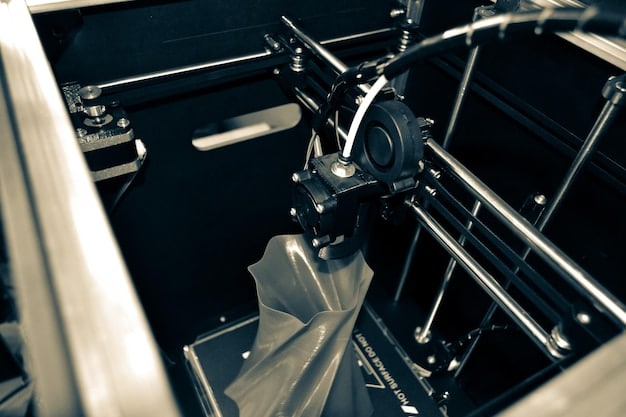

3D printing, or additive manufacturing, involves building three-dimensional objects layer by layer from a digital design. In the aerospace industry, this technology is used to create a wide range of components, from small, intricate parts to large structural elements. Understanding the fundamentals of this technology is crucial to appreciating its impact.

Materials Used in 3D Printing for Aerospace

Aerospace applications demand high-performance materials that can withstand extreme conditions. Common materials used in 3D printing include:

- Titanium Alloys: Known for their high strength-to-weight ratio and corrosion resistance, ideal for structural components.

- Nickel-Based Alloys: Used in high-temperature applications such as engine parts due to their excellent heat resistance.

- Aluminum Alloys: Lightweight and suitable for various airframe components.

- Polymers: Offering design flexibility and cost-effectiveness for interior parts and non-structural applications.

Key 3D Printing Technologies Applied

Several 3D printing technologies are utilized in the aerospace sector, each with its own advantages:

- Selective Laser Melting (SLM): Uses a laser to melt and fuse powdered metal layers, creating dense, strong parts.

- Electron Beam Melting (EBM): Employs an electron beam to melt metal powders in a vacuum, suitable for high-temperature alloys.

- Fused Deposition Modeling (FDM): Extrusions thermoplastic polymers layer by layer, commonly used for prototyping and tooling.

- Stereolithography (SLA): Uses a UV laser to cure liquid resin, creating highly detailed and accurate parts.

By understanding these basic principles and technologies, aerospace companies can better assess the potential benefits of integrating 3D printing into their operations.

Cost Reduction Strategies with 3D Printing

One of the most significant advantages of 3D printing in aerospace is its ability to reduce costs across various stages of the manufacturing process. From material usage to tooling expenses, 3D printing offers a range of strategies for achieving economic efficiency.

Minimizing Material Waste

Traditional manufacturing methods often involve subtractive processes, where material is removed to create the desired shape, leading to significant waste. 3D printing, however, only uses the material needed for the part, dramatically reducing waste and associated costs.

This is particularly beneficial for expensive aerospace-grade materials like titanium and nickel alloys, where waste can significantly impact overall costs. By minimizing material waste, aerospace companies can achieve substantial savings.

Reducing Tooling Costs

Traditional manufacturing often requires expensive tooling and molds, which can be time-consuming and costly to produce. 3D printing eliminates the need for much of this tooling, as parts are built directly from digital designs.

The reduction in tooling costs is especially significant for complex or customized parts, where traditional manufacturing methods would require extensive and costly tooling modifications. 3D printing allows for on-demand customization without the added expense.

Streamlining the Supply Chain

3D printing enables aerospace companies to produce parts on-site or closer to their operations, reducing the need for extensive supply chains. This can lead to lower transportation costs, shorter lead times, and greater control over the manufacturing process.

By streamlining the supply chain, companies can also reduce the risk of disruptions and delays, ensuring a more reliable and efficient operation. The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency is making manufacturing more agile and responsive.

In conclusion, cost reduction through 3D printing in the aerospace industry is achieved by minimizing material waste, reducing tooling costs, and streamlining the supply chain. These advantages contribute to significant economic benefits and enhance the competitiveness of aerospace manufacturers.

Improving Efficiency in Aerospace Manufacturing

Besides cost reduction, 3D printing significantly improves efficiency in aerospace manufacturing by accelerating production times, enabling design optimization, and facilitating rapid prototyping.

Accelerated Production Times

3D printing can significantly reduce the time it takes to manufacture aerospace components. Parts can be produced in hours or days, compared to weeks or months with traditional methods. This speed is particularly crucial for urgent repairs and maintenance.

Design Optimization and Customization

3D printing enables the creation of complex geometries and intricate designs that would be impossible or too costly to produce using traditional methods. This design freedom allows engineers to optimize parts for performance, weight, and functionality.

Moreover, 3D printing facilitates customization, allowing for the production of tailored parts to meet specific customer needs or unique application requirements. This level of customization enhances product value and competitiveness. The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency leads to innovative designs and tailored solutions.

Rapid Prototyping

The ability to quickly produce prototypes is another key advantage of 3D printing. Engineers can rapidly iterate on designs, test different materials, and refine parts with minimal time and cost. This accelerates the development process and enables faster innovation.

- Faster Design Iterations: Quickly test and refine designs.

- Material Exploration: Experiment with different materials to optimize performance.

- Reduced Development Costs: Minimize expenses associated with traditional prototyping methods.

By accelerating production times, enabling design optimization, and facilitating rapid prototyping, 3D printing significantly improves efficiency in aerospace manufacturing. These advancements lead to faster innovation, better product performance, and greater competitiveness.

The Impact of The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency on Supply Chains

Supply chains are critical for the aerospace industry – The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency affects everything from the speed of delivery to cost.

Localized Production

One of the most profound impacts of 3D printing is the potential for localized production. Instead of relying on centralized manufacturing facilities, aerospace companies can set up smaller, decentralized production units closer to their operations or customers.

This localized production model reduces transportation costs, shortens lead times, and enhances supply chain resilience. It also allows for greater flexibility in responding to changing market demands and customer needs.

Reduced Inventory

3D printing enables on-demand manufacturing, which means parts can be produced only when they are needed. This reduces the need for large inventories, freeing up capital and reducing storage costs. In addition, the technology helps reduce production times, which are frequently one of the most significant headaches related to supply chains.

Simplified Logistics

By producing parts closer to the point of use, 3D printing simplifies logistics and reduces the complexity of the supply chain. This leads to lower shipping costs, reduced risk of damage or loss during transit, and improved overall efficiency.

The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency can revolutionize the supply chain. Here are some ways:

- Reduced reliance on long-distance shipping routes.

- Improved responsiveness to customer needs and market changes.

- Greater control over the manufacturing process and product quality.

In essence, 3D printing is transforming the aerospace supply chain by enabling localized production, reducing inventory requirements, and simplifying logistics. These changes contribute to a more agile, resilient, and cost-effective supply chain.

Challenges and Future Trends

While 3D printing offers numerous benefits to the aerospace industry, there are also challenges that need to be addressed to fully realize its potential.

Scalability and Production Volume

One of the main challenges is scaling up production to meet the high-volume demands of the aerospace industry. 3D printing is well-suited for producing small quantities of customized parts, but scaling up to mass production requires significant investment in equipment and infrastructure.

Addressing this challenge requires developing more efficient and automated 3D printing processes, as well as integrating 3D printing into existing manufacturing workflows. Additionally, companies must be committed to upskilling their personnel. The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency can only be fully realized when scalability challenges are overcome.

Material Certification and Quality Control

Ensuring the quality and reliability of 3D-printed parts is crucial for aerospace applications, where safety is paramount. Developing robust material certification processes and quality control standards is essential to gain confidence in 3D-printed parts.

This requires collaboration between industry stakeholders, regulatory agencies, and research institutions to establish clear guidelines and best practices for the use of 3D printing in aerospace. 3D printing technologies impact the economics and the quality of work performed, leading to better and more useful projects.

Emerging Trends in 3D Printing

Despite the challenges, several emerging trends are poised to further revolutionize 3D printing in aerospace:

- Multi-material Printing: Combining different materials in a single print to create parts with tailored properties and functionalities.

- Continuous Fiber Fabrication: Embedding continuous fibers into 3D-printed parts to enhance their strength and stiffness.

- Artificial Intelligence (AI) Integration: Using AI to optimize designs, control printing processes, and predict part performance.

AI integration is poised to transform the way engineers interact with 3D printing, and the possibilities of AI in The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency are nearly endless.

By addressing the challenges and embracing emerging trends, the aerospace industry can unlock the full potential of 3D printing. These advancements will lead to even greater cost savings, efficiency gains, and product innovation.

| Key Point | Brief Description |

|---|---|

| 🚀 Cost Reduction | 3D printing minimizes material waste and tooling costs, leading to significant savings. |

| ⏱️ Efficiency Improvement | Accelerated production, design optimization and rapid prototyping. |

| ⛓️ Supply Chain Impact | Localized production, reduced inventory, and simplified logistics. |

FAQ

3D printing reduces costs by minimizing material waste, eliminating the need for expensive tooling, and streamlining the supply chain, leading to substantial savings for aerospace manufacturers.

Common materials include titanium alloys, nickel-based alloys, aluminum alloys, and polymers. These materials are chosen for their high strength, heat resistance, and lightweight properties.

Accelerated production times allow for faster repairs, quicker design iterations, and reduced lead times, enabling aerospace companies to respond more rapidly to changing market demands, a clear Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency.

On-demand manufacturing reduces the need for large inventories, simplifies logistics, and enables localized production, making the supply chain more agile and responsive to specific customer needs.

Challenges include scalability, material certification, and quality control. Emerging trends like multi-material printing, continuous fiber fabrication, and AI integration promise to further revolutionize the space. These advance The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency.

Conclusion

The Impact of 3D Printing on the US Aerospace Industry: Reducing Costs and Improving Efficiency is undeniable. By minimizing waste, reducing production times, and enabling design innovation, 3D printing is revolutionizing how aircraft components are manufactured. The benefits are considerable, and are only growing.

As technology advances and challenges are overcome, the aerospace industry can expect even greater efficiency gains, cost savings, and product innovation. Embracing 3D printing is no longer a luxury but a necessity for aerospace companies seeking to remain competitive in the global market.